Aerospace Finishing

A fleet of technologies

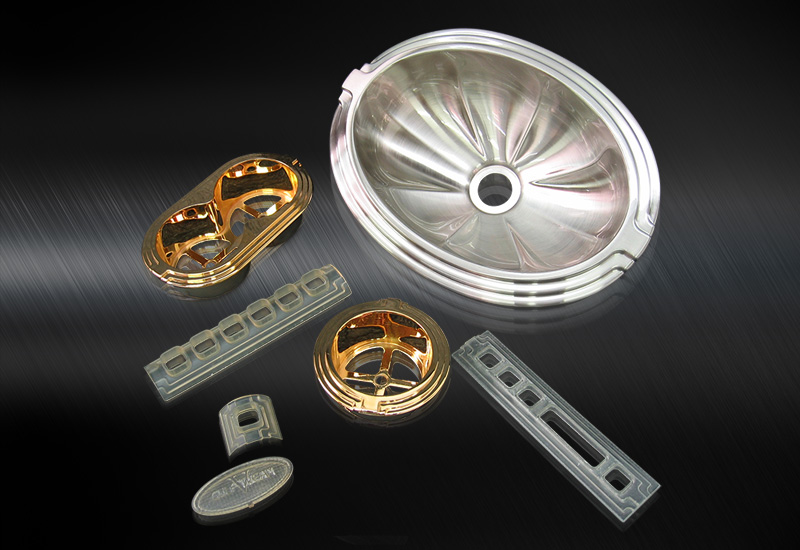

Aerospace companies serve some of the most exclusive and demanding clients relative to appearance. QCP leverages diversity, flexibility and cutting-edge technology to deliver optimal solutions. Our selection of quality finishes and variety of decorative processes is second to none.

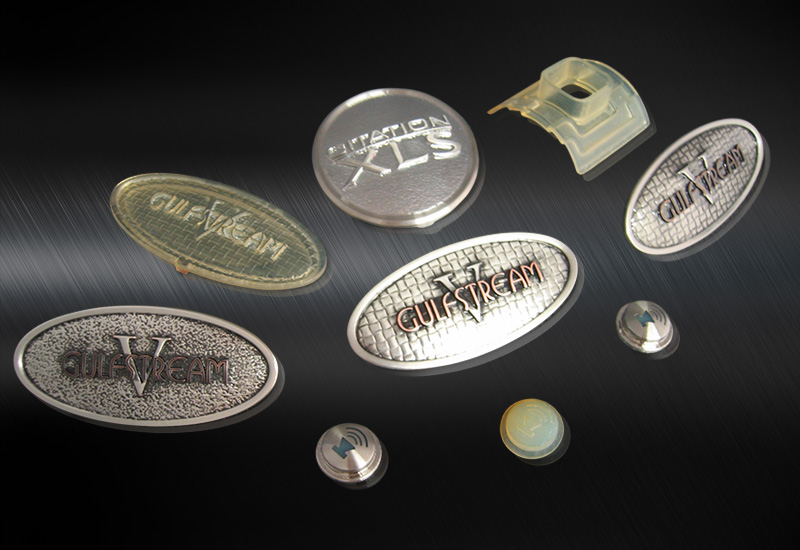

We partner with some of the largest and most discriminating aircraft manufacturers, completion centers, part manufacturing and refurbishment shops in the world. Our clients include leading aerospace companies such as Gulfstream, Cessna, Bombardier, Rockwell Collins, B/E Aerospace, Honda and Learjet.

QCP provides parts and durable finishes, flightworthy and lightweight parts for luxury cabin environments. From faucets and fixtures to hardware and switches, we are equipped to plate any visible surface. We are one of the only finishing companies in the U.S. that can facilitate product from concept to full-scale production.

Elevating ease and flexibility

The use of materials and technologies previously reserved for the consumer market is soaring. Now, materials such as plastic, composites and polymer can be finished to enhance any aircraft interior. This increases design flexibility, while significantly reducing weight.

- Refurbishment of interior aircraft parts

- With our partners, QCP can provide print to production

- Finishes for all interior parts and visible plating surfaces

- Custom color matching for decorative and interior products

Setting the highest industry standards

At QCP, we don’t sacrifice durability for appearance. We understand that client demands and expectations are high. That’s why our commitment to customer service is second to none.

- AS9100-certificated facilities (QCP Whittier, QCP Brunswick, PG Imtech of CA)

- FAA-certificated repair station (QCP Whittier, Quaker City Plating only)

- In-house testing capabilities (Not AS9100 Certified Lab)

- Superior process control and on-time delivery

Committed to quality

Each part undergoes repeated inspection and testing at our in-house quality assurance lab, from prototype to production. We take pride in our reputation as a considerate corporate neighbor – surpassing all environmental regulations while minimizing impact on the world around us.

- Salt spray

- CASS

- Thermal cycle

- Thickness (Kocour)

- STEP

- Adhesion (Instron)

- Microsection

- Others

Testing is performed to Customer Specifications, testing will be performed in Non-AS9100 certified lab unless specifically required by customer PO. If required by PO, parts will be outsourced to an accredited lab.

A fleet of technologies

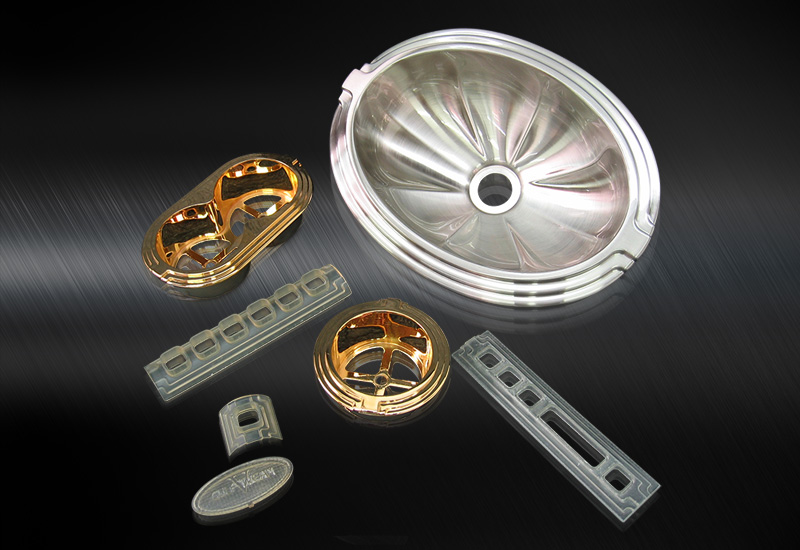

Aerospace companies serve some of the most exclusive and demanding clients relative to appearance. QCP leverages diversity, flexibility and cutting-edge technology to deliver optimal solutions. Our selection of quality finishes and variety of decorative processes is second to none.

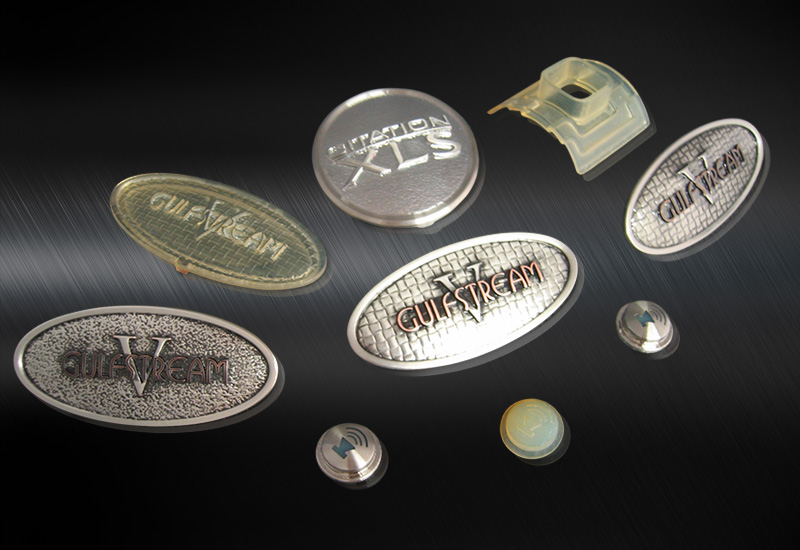

We partner with some of the largest and most discriminating aircraft manufacturers, completion centers, part manufacturing and refurbishment shops in the world. Our clients include leading aerospace companies such as Gulfstream, Cessna, Bombardier, Rockwell Collins, B/E Aerospace, Honda and Learjet.

QCP provides parts and durable finishes, flightworthy and lightweight parts for luxury cabin environments. From faucets and fixtures to hardware and switches, we are equipped to plate any visible surface. We are one of the only finishing companies in the U.S. that can facilitate product from concept to full-scale production.

Elevating ease and flexibility

The use of materials and technologies previously reserved for the consumer market is soaring. Now, materials such as plastic, composites and polymer can be finished to enhance any aircraft interior. This increases design flexibility, while significantly reducing weight.

- Refurbishment of interior aircraft parts

- With our partners, QCP can provide print to production

- Finishes for all interior parts and visible plating surfaces

- Custom color matching for decorative and interior products

Setting the highest industry standards

At QCP, we don’t sacrifice durability for appearance. We understand that client demands and expectations are high. That’s why our commitment to customer service is second to none.

- AS9100-certificated facilities (QCP Whittier, QCP Brunswick, PG Imtech of CA)

- FAA-certificated repair station (QCP Whittier, Quaker City Plating only)

- In-house testing capabilities (Not AS9100 Certified Lab)

- Superior process control and on-time delivery

Committed to quality

Each part undergoes repeated inspection and testing at our in-house quality assurance lab, from prototype to production. We take pride in our reputation as a considerate corporate neighbor – surpassing all environmental regulations while minimizing impact on the world around us.

- Salt spray

- CASS

- Thermal cycle

- Thickness (Kocour)

- STEP

- Adhesion (Instron)

- Microsection

- Others

Testing is performed to Customer Specifications, testing will be performed in Non-AS9100 certified lab unless specifically required by customer PO. If required by PO, parts will be outsourced to an accredited lab.