Rapid Prototype Manufacturing

Quickly bringing concepts to life

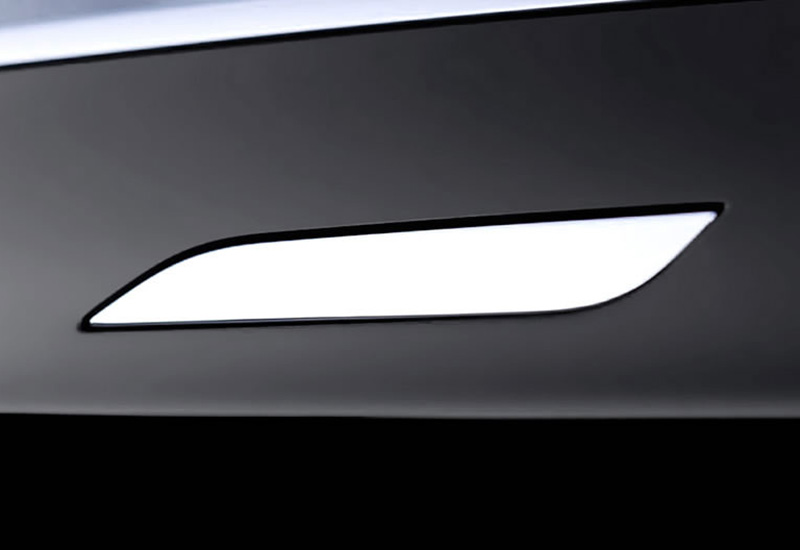

Need prototypes or a small quantity of parts? QCP can quickly turn your CAD file into a prototype or production product. There’s no more waiting to see the effect of plating on your concepts. Cut one purchase order, send your file and we’ll deliver the product. Parts may be produced in an affiliated Non-AS9100 certified facility.

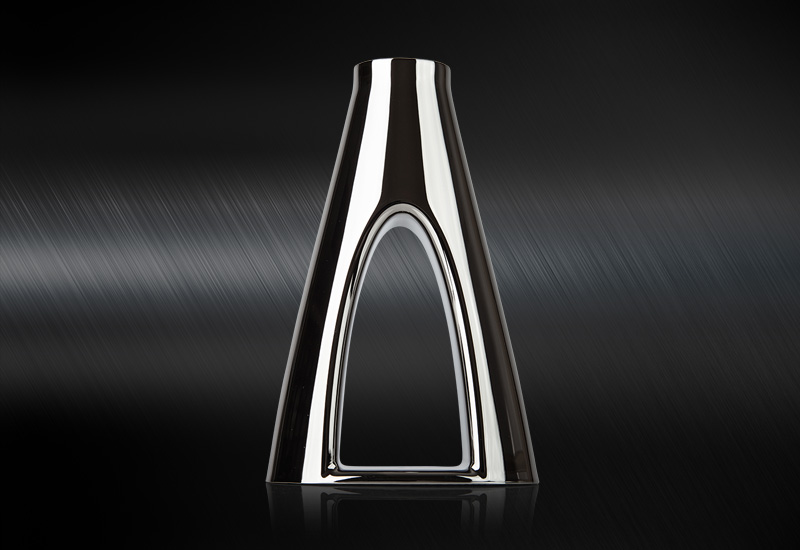

Concept models are used to evaluate new designs or introduce products early in the design process. You can quickly evaluate what works and what needs improvement. QCP serves a wide range of industries, building everything from famous movie props to fine aircraft cabin appointments.

We’ve provided solutions to Ford, Honda, Tesla, Hyundai, Chrysler, Volkswagen, Newell Coach and B/E Aerospace. For the professionals at QCP, not job is too simple or elaborate. Whether you’re an OEM designer, industrial manufacturer or contract prototype bureau, we make your parts shine.

Investing in the future

QCP has a long history of investing in the future through ongoing research and development. We have successfully improved the finishing techniques, solutions and chemistry of our trade. We’re equipped to meet requirements for the most difficult applications.

Need a new finish, more durability or plating on a unique material? We may already have the solution. QCP offers plating for fiberglass, urethane, PC/ABS, carbon fiber, thermoplastics and other non-conductive materials.

Setting the highest industry standards

At QCP, we don’t sacrifice durability for appearance. We understand that client demands and expectations are high. That’s why our commitment to customer service is second to none.

- AS9100-certificated facilities (QCP Whittier, QCP Brunswick, PG Imtech of CA)

- FAA-certificated repair station (QCP Whittier, Quaker City Plating only)

- In-house testing capabilities (Not AS9100 Certified Lab)

- Superior process control and on-time delivery

Committed to quality

Each part undergoes repeated inspection and testing at our in-house quality assurance lab, from prototype to production. We take pride in our reputation as a considerate corporate neighbor – surpassing all environmental regulations while minimizing impact on the world around us.

- Salt spray

- CASS

- Thermal cycle

- Thickness (Kocour)

- STEP

- Adhesion (Instron)

- Microsection

- Others

Testing is performed to Customer Specifications, testing will be performed in Non-AS9100 certified lab unless specifically required by customer PO. If required by PO, parts will be outsourced to an accredited lab.

Quickly bringing concepts to life

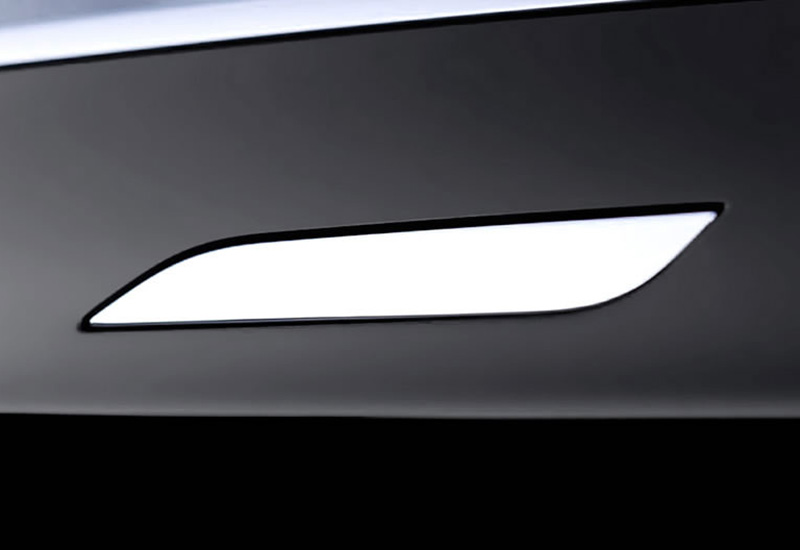

Need prototypes or a small quantity of parts? QCP can quickly turn your CAD file into a prototype or production product. There’s no more waiting to see the effect of plating on your concepts. Cut one purchase order, send your file and we’ll deliver the product. Parts may be produced in an affiliated Non-AS9100 certified facility.

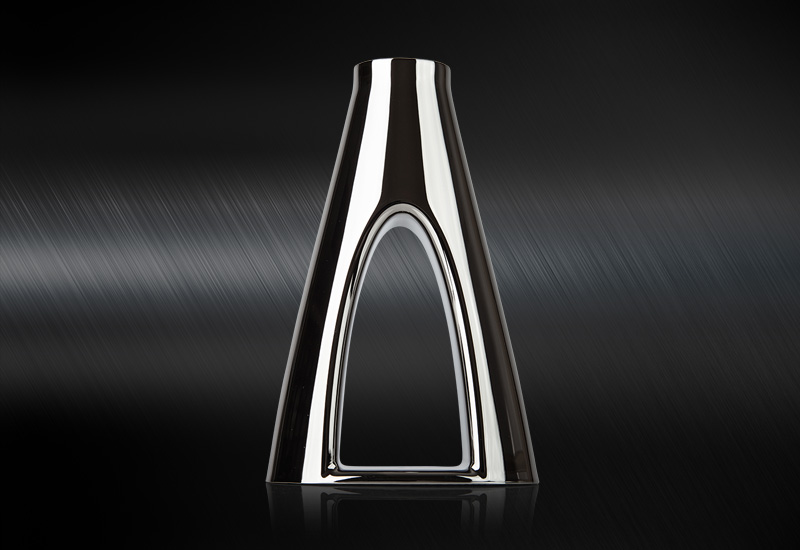

Concept models are used to evaluate new designs or introduce products early in the design process. You can quickly evaluate what works and what needs improvement. QCP serves a wide range of industries, building everything from famous movie props to fine aircraft cabin appointments.

We’ve provided solutions to Ford, Honda, Tesla, Hyundai, Chrysler, Volkswagen, Newell Coach and B/E Aerospace. For the professionals at QCP, not job is too simple or elaborate. Whether you’re an OEM designer, industrial manufacturer or contract prototype bureau, we make your parts shine.

Investing in the future

QCP has a long history of investing in the future through ongoing research and development. We have successfully improved the finishing techniques, solutions and chemistry of our trade. We’re equipped to meet requirements for the most difficult applications.

Need a new finish, more durability or plating on a unique material? We may already have the solution. QCP offers plating for fiberglass, urethane, PC/ABS, carbon fiber, thermoplastics and other non-conductive materials.

Setting the highest industry standards

At QCP, we don’t sacrifice durability for appearance. We understand that client demands and expectations are high. That’s why our commitment to customer service is second to none.

- AS9100-certificated facilities (QCP Whittier, QCP Brunswick, PG Imtech of CA)

- FAA-certificated repair station (QCP Whittier, Quaker City Plating only)

- In-house testing capabilities (Not AS9100 Certified Lab)

- Superior process control and on-time delivery

Committed to quality

Each part undergoes repeated inspection and testing at our in-house quality assurance lab, from prototype to production. We take pride in our reputation as a considerate corporate neighbor – surpassing all environmental regulations while minimizing impact on the world around us.

- Salt spray

- CASS

- Thermal cycle

- Thickness (Kocour)

- STEP

- Adhesion (Instron)

- Microsection

- Others

Testing is performed to Customer Specifications, testing will be performed in Non-AS9100 certified lab unless specifically required by customer PO. If required by PO, parts will be outsourced to an accredited lab.